Building a DIY workbench is like giving your creativity a home – a sturdy and reliable space where your projects can come to life. Whether you’re a seasoned DIY enthusiast or just starting to explore the world of hands-on projects, having a workbench tailored to your needs is a game-changer. In this guide, we’ll walk you through the simple yet rewarding process of creating your very own workbench.

Picture this: a workspace that not only stands up to the demands of your projects but also reflects your style and preferences. That’s the beauty of a DIY workbench – it’s more than just a piece of furniture; it’s a functional canvas for your creativity.

No matter the size of your workshop or the scope of your projects, a well-designed workbench forms the heart of it all. From woodworking wonders to simple repairs, your workbench is there to support you. In the following pages, we’ll break down the process into easy-to-follow steps, providing tips and relatable examples to guide you through the journey.

So, whether you’re dreaming of a compact bench for your garage or envisioning a multipurpose workspace that adapts to your various projects, this guide is your starting point. Let’s roll up our sleeves, gather some basic materials, and embark on the fulfilling journey of creating a DIY workbench that’s as unique as the projects you’ll bring to life on it.

Get ready to craft a space where your ideas take shape, and your DIY adventures find their home.

Read also: DIY – How to Make Homemade Earrings

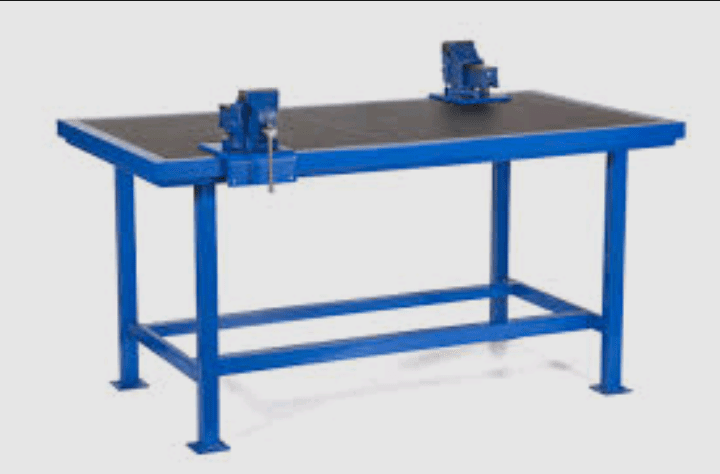

DIY Workbench

I. Choosing the Right Design

Before diving into the construction process, it’s crucial to choose a workbench design that aligns with your project requirements and available space. The three primary types of workbenches are the traditional woodworking bench, the versatile multipurpose bench, and the compact garage or basement workbench.

- Traditional Woodworking Bench

If your focus is primarily on woodworking projects, a traditional woodworking bench may be the best fit. These benches often feature a thick, sturdy top that provides a stable surface for sawing, planing, and other woodworking tasks. Consider adding features such as built-in vises and tool storage to enhance functionality.

- Multipurpose Bench

For those who engage in a variety of DIY projects, a multipurpose bench offers versatility. This type of bench typically includes storage space, adjustable height options, and provisions for clamping tools. A multipurpose bench accommodates various activities, from woodworking to metalworking and beyond.

- Garage or Basement Workbench

If space is limited, a compact garage or basement workbench is an excellent choice. These benches are designed to fit into smaller areas while still providing a solid workspace. Consider incorporating fold-down extensions or wheels for easy mobility.

II. Materials and Tools

Once you’ve chosen a design, gather the necessary materials and tools. The basic materials for a DIY workbench include lumber, plywood or MDF (medium-density fiberboard) for the top, screws, wood glue, and a finish of your choice. Additionally, you’ll need a variety of tools, such as a saw, drill, screwdriver, measuring tape, and clamps.

- Lumber

Selecting the right type of lumber is crucial for the durability and stability of your workbench. Hardwoods like oak, maple, or birch are excellent choices for the top surface, providing strength and resistance to wear. For the frame, softwoods like pine or fir are cost-effective options.

- Plywood or MDF

Plywood or MDF are ideal choices for the workbench top. They offer a smooth and flat surface, making them suitable for various DIY activities. Plywood is known for its strength, while MDF provides a smooth and consistent surface.

- Screws and Wood Glue

Using the right screws is essential for a sturdy workbench. Choose screws that are appropriate for the type of wood you’re working with. Wood glue is crucial for reinforcing joints and enhancing overall stability. Combining screws and glue creates a strong bond that will withstand the test of time.

- Finish

Applying a finish to your workbench not only enhances its appearance but also protects it from moisture and wear. Popular finish options include polyurethane, varnish, or a simple coat of paint. Choose a finish that complements your workshop environment and personal style.

III. Construction Process

With your materials and tools ready, let’s dive into the construction process. We’ll break down the steps for building a basic woodworking bench, but feel free to adapt these instructions to your chosen design.

- Design and Planning

Before making any cuts, create a detailed plan for your workbench. Consider the dimensions, including the height, width, and depth, and sketch out a rough design. This planning stage is crucial for visualizing the final product and avoiding mistakes during construction.

- Cutting the Lumber

Start by cutting the lumber according to your design specifications. Use a saw to make precise cuts for the legs, frame, and any additional components. Remember to measure twice and cut once to ensure accuracy.

- Assembling the Frame

Assemble the frame by attaching the legs to the top and bottom frame pieces. Use wood glue and screws to secure the joints. Make sure the frame is square by measuring diagonally from corner to corner, and adjust as needed.

- Adding Supports and Braces

To enhance the stability of your workbench, add supports and braces between the legs. This step is crucial, especially for larger workbenches. Use screws and wood glue to secure these components, ensuring a solid and rigid structure.

- Attaching the Top

Once the frame is complete, it’s time to attach the top. Place the plywood or MDF on top of the frame and secure it with screws. Ensure that the top is flush with the frame on all sides for a smooth and even work surface.

- Finishing Touches

Sand the entire workbench to smooth any rough edges or surfaces. Apply your chosen finish to protect the wood and enhance its appearance. Allow the finish to dry thoroughly before moving on to the next step.

Read also: DIY Projects for Home Decor

IV. Customization and Personalization

Now that your basic workbench is complete, consider customizing it to meet your specific needs. Here are some ideas for personalizing your DIY workbench:

- Tool Storage

Incorporate drawers, shelves, or pegboards to organize and store your tools efficiently. This not only keeps your workspace tidy but also ensures that your tools are easily accessible during projects.

- Built-In Vises

If you’re building a woodworking bench, consider adding built-in vises to secure your workpieces. A front vise and a tail vise provide versatility for a wide range of woodworking tasks.

- Adjustable Height

For a multipurpose bench, consider incorporating an adjustable height mechanism. This allows you to customize the workbench to different tasks, such as standing or sitting while working.

- Electrical Outlets

If you frequently use power tools, consider adding electrical outlets to your workbench. This convenient feature eliminates the need for extension cords, providing a safer and more organized workspace.

- Lighting

Ensure adequate lighting for your workbench by adding task lighting. This can be achieved with adjustable LED lights or mounted fixtures, reducing eye strain and improving visibility during intricate tasks.

V. Examples of DIY Workbench Customization

Let’s explore a couple of examples of how DIY enthusiasts have personalized their workbenches:

- Tool Organization and Storage: John, an avid woodworker, customized his workbench by adding a pegboard on the wall behind it. This pegboard holds various hooks and shelves, providing organized storage for his hand tools, measuring instruments, and safety gear. By having everything within arm’s reach, John maximizes efficiency during his woodworking projects.Tip: When organizing tools, group them by type or use to make it easy to locate what you need.

- Adjustable Height and Mobility: Sarah, a DIY enthusiast with a small workshop, designed her workbench with adjustable height legs and wheels. This allows her to easily move the workbench around and adjust its height based on the task at hand. Whether she’s working on a detailed project that requires precision or a larger project that demands more space, Sarah’s workbench adapts to her needs.Tip: Lockable wheels provide stability when needed and mobility when you want to reposition your workbench.

VI. Maintaining Your DIY Workbench

Congratulations on completing your DIY workbench! To ensure its longevity and optimal performance, it’s essential to implement a regular maintenance routine. Here are some tips for maintaining your workbench:

- Clean Regularly: Keep your workbench clean by wiping away dust and debris after each project. This prevents the accumulation of materials that could scratch the surface or interfere with moving parts.

- Inspect Joints and Fasteners: Periodically inspect the joints and fasteners for any signs of wear or looseness. Tighten screws as needed and replace any damaged components to maintain the structural integrity of your workbench.

- Protect the Surface: Use sacrificial boards or mats when engaging in activities that could potentially damage the workbench surface, such as hammering or using sharp tools. This helps preserve the integrity of the top over time.

- Reapply Finish as Needed: Depending on the type of finish you applied, it may need to be reapplied over time. Keep an eye on the condition of the finish, and refresh it as necessary to protect the wood from moisture and wear.

- Store Tools Properly: Return tools to their designated storage spaces after each use. This not only keeps your workspace organized but also prevents tools from rolling off the bench or getting damaged.

Read also: Waste To Fertilizer: What You Need to Know